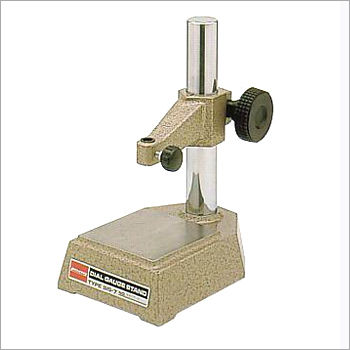

Thickness Gauge

Thickness Gauge Price And Quantity

- 50-100 Piece

- 2000.00 - 10000.00 INR/Piece

Thickness Gauge Trade Information

- 500 Piece Per Day

- 5-7 Days

Product Description

Ultrasonic Thickness Gauges are designed to improve safety and ensure reliability of material subject to corrosion or erosion.

Corrosion gauges with their dual-element transducers are the primary inspection tool used to measure the remaining walls of components such as pipelines, pressure vessels, storage tanks, and numerous other applications..

Precision gauges use single-element transducers to provide the thinnest range and highest degree of accuracy possible. Common applications include metals and a variety of non-metals (i.e. glass, ceramic, plastic, etc.).

Specifications:

| Measuring Range | 0.65 mm 400mm (upto 500mm) (in steel) |

| Sound Velocity | 1000~9999 m/s |

| Resolution | 0.01mm/0.1mm or 0.001/0.01 selectable |

| Units | mm/inch (selectable) |

| Memory | Upto 2000 Groups (up to 99 Values for each file) |

| Accuracy | ( 0.5%Thickness+0.04 ) mm |

| Alarm | preset upper and lower limit |

| Work voltage | 3V( 2 AA alkaline battaries) |

| Work mode | Single point and scan |

| Interface port | USB |

| Dimensions | 136 x 72 x 20mm |

| Weight | 177 g |

| Display | 3.5 digit LCD with EL back light |

| Continuous working period | 280 hours (with EL back light off) |